Addressing Temperature Effects In Turning

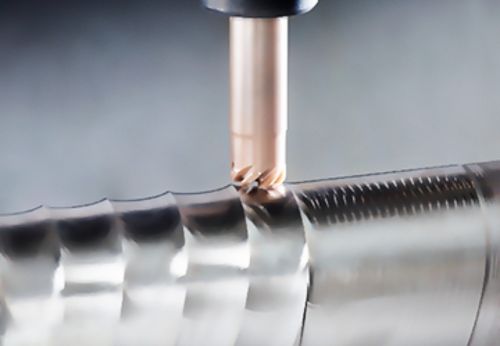

One of the most serious enemies of carbide inserts is the high temperature of the materials that results from the machining process. Here’s how high temperatures in machining are being addressed through the latest insert technologies. Article by ISCAR.

Cooling is essential to the machining world, where appropriate cooling can significantly increase insert life and reduce manufacturing costs, due to the changes in chip shape and the resulting temperature during the machining process.

In the last few years, the concept and implementation of cooling solutions for cutting tools has enjoyed a surge of popularity and enthusiasm as if it had never existed before. CNC machine manufacturers throughout the world have invested time and resources to develop solutions that can supply coolant at high pressures and today all new machines are supplied with a high-pressure coolant option.

Manufacturers from industries such as aerospace, automotive, and large part production appreciate the immense advantage of supplying coolant directly to the cutting edge and are only ordering machines for milling centers or turning centers with high pressure coolant capabilities—minimum 70 bar and up to 300 bar. Mass production manufacturers are also benefiting from the integration of ISCAR’s JETCUT tools into their processes.

One of the most serious enemies of carbide inserts is the high temperature of the materials that results from the machining process. Temperatures vary, depending both on the properties of the metal that is being machined and on environmental work conditions. The average temperature during machining can range from 300 deg C to 900 deg C.

As the temperature rises, the lifespan of the inserts is shortened. Increased wear can damage workpiece quality and negatively affect machining properties: the heat generated between the insert and the workpiece can cause a change in chip shape and plastic deformation of the insert.

High pressure starting at 70 bar can be effective in breaking chips and, in cases when it is difficult to break chips and the chip formed is long and curled, coolant applied correctly and under high pressure can solve this problem.

Judicious application of coolant can prevent the workpiece materials from deformation and can act as protectant for the machine. In many cases, effective and efficient cooling can actually mean the difference between profit and loss.

Cooling Technology

Cooling has a major influence on machining exotic materials such as Inconel, Titanium, Hastelloy, Monel and other alloys, which are all used in the aerospace industry. These workpiece materials are difficult to machine as they have a very high nickel level and possess a tendency to stick to cutter edges due to their elastic, sticky and ductile properties – which is one of the reasons that parts for the aerospace industry are extremely expensive. Machining these types of materials without coolant is almost impossible, as the high temperatures and stickiness cause instantaneous wear and premature failure for carbide inserts.

In addition to reducing temperatures for exotic metals, the use of coolant creates a shielded area between the insert and the workpiece material, so preventing material from sticking to the cutting edge – which is a major factor in premature failure for inserts.

In groove turn operations, it is particularly important to select the right grade for chip breaking. An incorrect choice of grade or chip breaker can spell disaster for the manufacturer. In addition, cooling has a significant effect on chip breaking effectiveness and correct coolant application can mean the difference between success and failure.

After researching and studying the influence of coolant on its inserts, ISCAR applied the scientific knowledge acquired to the successful implementation of new and groundbreaking cooling technologies in turning operations. The company developed and integrated external and internal tools to deliver coolant directly to the cutting edge, including the JETCUT range. This has succeeded in increasing tool lifespan and productivity and, even at low pressures such as 10 or 20 bar, the advantages of directing coolant flow straight at the cutting edge can be seen in the reduction of temperature during machining.

Manufacturers engaging in high volume machining have noted a substantial increase in tool life and productivity after integrating JETCUT tools to pinpoint coolant directly to the cutting zone. This is because lowering the temperature in this way facilitates longer tool life, increasing cutting conditions such as speed and feed.

Manufacturers who work with problematic exotic materials such as Inconel, titanium and stainless steels have also managed to achieve higher productivity by incorporating JETCUT tools. Pinpointing high pressure coolant straight onto the cutting zone prevents a sticky edge, consequently extending tool life.

In response to the growing demands of many industry sectors, ISCAR expanded its jet high pressure line by adding turning tools fitted with the JET-R-TURN hollow rigid clamp, which also acts as a coolant nozzle. Until now, ISCAR’s ISOTURN range of tools featuring a jet high pressure cooling option were designed with a lever clamping mechanism, as an upper clamp would obstruct the coolant jet from reaching the cutting edge.

The new design enables jet high pressure coolant to reach the cutting edge without any obstacles.

ISCAR offers tools with JET-R-TURN Rigid Clamp mechanism for the most popular standard CNMG, WNMG and DNMG insert geometries. It features strong and reliable clamping mechanism, which prolongs tool life; directs the coolant jet directed to the cutting edge; and has excellent corner location repeatability and performance in heavy cut machining.

The new external tools feature three coolant connection options: rear threaded inlet, bottom threaded inlet, and bottom inlet for adjustable shank overhang, as in ISCAR’s JHP-MC tools.

All external tools are equipped also with a frontal bottom coolant outlet directed to the insert flank, which enhances the cooling effect. The through-tool coolant provides improved tool life, chip control and productivity advantages when high pressure coolant is induced. In addition, the 10–15 bar standard pressure provides better performance when compared to external cooling results.

Every Second Counts

What is a second in our life? Every second can be multiplied and translated to millions of seconds when considering mass production of standard parts. Saving a single second times a million parts is equivalent to a whole working month, which represents a major savings and is the dream of every mass production manufacturer.

And ISCAR’s wide range of JETCUT tools for a variety of applications, from turning and grooving to parting, helps manufacturers achieve this, and more.

Read more:

Stability Across A Broad Spectrum

Sandvik Coromant’s CoroBore 825 Damped Fine-Boring Tool Improves Security And Productivity

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

FOLLOW US ON: LinkedIn, Facebook, Twitter

Successful development of innovative and dynamic parts in today’s miniature dental and medical components industry presents a formidable and equally dynamic challenge to cutting tool manufacturers.

Successful development of innovative and dynamic parts in today’s miniature dental and medical components industry presents a formidable and equally dynamic challenge to cutting tool manufacturers. SwissCut tools are used in the face and OD turning (screw head turning) operation, while the drilling operation is performed by SOLIDDRILL solid carbide drills with 3xD and 5xD drilling depths and right-hand cut. The drills feature coolant holes.

SwissCut tools are used in the face and OD turning (screw head turning) operation, while the drilling operation is performed by SOLIDDRILL solid carbide drills with 3xD and 5xD drilling depths and right-hand cut. The drills feature coolant holes. Semi-finish internal turning is performed by ISOTURN inserts with SWISSTURN toolholders, while the cut-off operation uses DO-GRIP twisted double-sided parting inserts which feature double-ended twisted geometry for no depth of cut limitation.

Semi-finish internal turning is performed by ISOTURN inserts with SWISSTURN toolholders, while the cut-off operation uses DO-GRIP twisted double-sided parting inserts which feature double-ended twisted geometry for no depth of cut limitation. SolidMill three-flute, 30 deg helix short solid carbide ball nose endmills are employed for the profile milling operation, and SolidMill endmills with four flutes, 38 deg helix and variable pitch for chatter dampening with 3xD relieved necks are utilized for face milling.

SolidMill three-flute, 30 deg helix short solid carbide ball nose endmills are employed for the profile milling operation, and SolidMill endmills with four flutes, 38 deg helix and variable pitch for chatter dampening with 3xD relieved necks are utilized for face milling.