Investigating Process Parameters And Optimisation In EDM

Odisha-based Assistant Professor Ritesh Kumar Hui of Aryan Institute of Engineering & Technology, and Dr Chandrabhanu Malla of KIIT University present their findings on boundaries concerning electrical discharge machining (EDM).

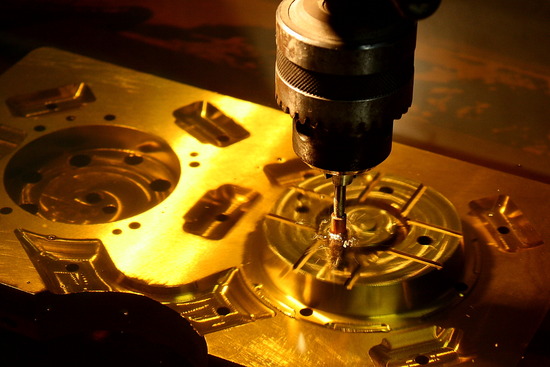

Among the thermal mode of machining, electrical discharge machining (spark erosion machining) is mainly a method for the manufacturing of a multitude of ever changing geometries very often produced as unit job or in small batches. The basic concept of Electrical Discharge Machining (EDM) process is creating out of metals affected by the sudden stoppage of the electron beam by the solid metal surfaces of the anode.

The portion of the anode facing the direct electrical pulse reaches the boiling point. Even in case of medium long pulse the rate of temperature increases in tens of millions of degree per second which means dealing with an explosion process.

In the present work, a combined optimisation approach is used for the estimation of maximum metal removal rate (MRR) and minimum tool wear rate (TWR), surface roughness (SR) and overcut (OC) of produced in EDM. The important input parameters current (I), pulse on time (Ton), pulse off time (Toff) and voltage (V) are considered.

Read on for more —> https://rb.gy/ptlse1

What You Missed:

Volkswagen To Speed Up Electric Vehicle Transition

Great Wall Motor Thailand Offers Tips For Electric Vehicle Users

Not Enough Lithium Globally To Meet Electric Vehicle Targets

Honda To Set Up China Venture To Procure EV Batteries

Vale And Partners To Invest In Nickel Project In Indonesia

Metalworking Fluids Market Outlook By Industries And Areas

New-Vehicle Market Expands For Third Straight Month

Semiconductor Industry to End 2022 in Loss! Can Chip Makers Manage?

Investment Opportunities For Saudi Businesses In Indonesia

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

CONNECT WITH US: LinkedIn, Facebook, Twitter

Letter to the Editor

Do you have an opinion about this story? Do you have some thoughts you’d like to share with our readers? APMEN News would love to hear from you!

Email your letter to the Editorial Team at [email protected]