Humans And Robots—Welding Side By Side?

Poor concentration and fatigue is sometime you will never see with robots, which have always been seen by their human counterparts as reliable and indispensable “colleagues”. Contributed by Messe Dusseldorf

Robots are now increasingly handling the welding, bending, cutting, separation, transfer and storage of pipes and tubes. Thanks to artificial intelligence and machine learning, robots are set to become even more flexible and will eventually replace purely repetitive robots altogether.

Picture this—you turn up at work in the morning, and the first thing you do is switch on the television. It does not seem very appropriate at first sight. But this is precisely what is being turned into reality with the camera-controlled and fully electric manufacturing cell from transfluid—the element which is right at the heart of a smart tube forming system. What you can see “flickering” on a large screen is not the latest news bulletin, but valuable details about the energy consumption, process capacity value and quantity of the tubes formed up to now.

Robots As An Important Module

Robots are an important module at the transfluid tube forming centre and are used in the production of air conditioning lines. As well as a camera monitoring system, the plant has a magazine, a 4-axle handling system, two combination machines for tube forming purposes, a bending machine, a chamfering unit, a dot-matrix printer and two robots.

Before bending can start, one side of a tube is always handled in combination with a tube forming machine, while the other side is chiplessly cut after the bending process and is then also formed.

Should this be required, the robot subsequently holds the tube into a deburring device. “Both ends can be visually monitored via a camera. Alternatively, the robot holds the tube into a labelling unit where it can then be marked at all the required points—and in fact completely without any clamping device,” said Stefanie Flaeper, managing director of transfluid.

100 Percent Quality

Using a forming system with a rotary table, it would then be possible to join two tubes together with a flange. For the manufacturing process this means maximum safety, a high yield and documented quality —while information is provided on a large screen as a nice side-effect.

Robots have definitely proved their worth in pipe and tube forming. Ms Flaeper emphasised that they “ensure controlled handling” because a robot is, after all, ideally suited for the manufacturing of bent components.

She added,“On the other hand, they tend to be of lesser significance in the handling of long, straight tubes and pipes. Linear systems are faster for this purpose.” Robots are particularly widespread in machining, “because this involves either complex handling or manipulating heavy parts.”

Use In Welding

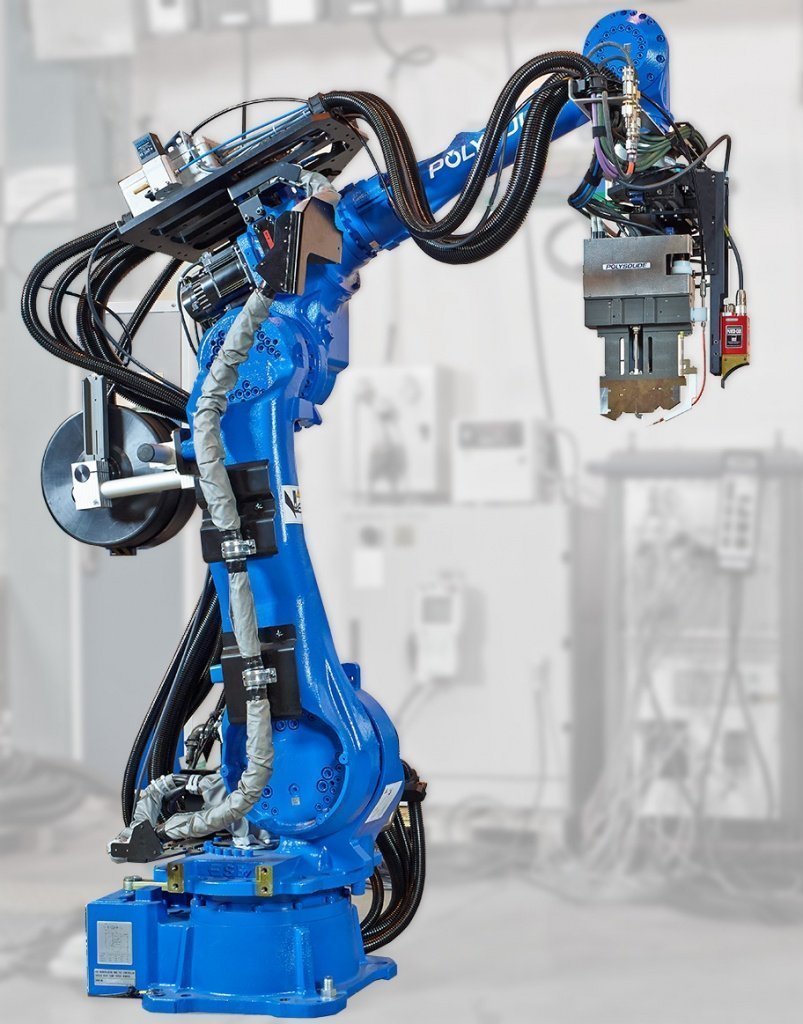

For Polysoude and its customers, robots are a good supplement to conventional automation solutions. A robot makes it possible to guide the torch along the pipes themselves in manual tungsten inert gas (TIG) welding, even where there is not much space. It also ensures “a high-quality seam thanks to the precision and reproducibility of movements in complex geometries,” said Hans-Peter Mariner, managing director of Polysoude.

Robots are generally very widespread in welding, but not particularly in TIG welding. According to Mr Mariner, TIG is used “almost never in conjunction with narrow gap welding or the welding of pipe-floor joints.” This is due to legal requirements which include, for instance, a shielded zone without user access—unlike conventional automation solutions. The company, however, allows the use of robots in TIG welding.

Robots And Nuclear Fusion

The essential criterion for choosing a specific type of robot is the level of precision which Mr Mariner states “is a matter of the TIG welding itself, even under full load, within a range of five to 10 mm.” Furthermore, he added that it was important for a robot to be easy to program and to have sensors, especially for smart tracking purposes.

The use of robots in TIG welding has achieved a certain amount of fame in one of the most ambitious projects in the world, called the International Thermonuclear Experimental Reactor (ITER). The project is to prove that nuclear fusion as an energy source can be used for electric power production without major carbon emissions. 35 countries are participating in the design of the planned Tokamaks nuclear fusion chamber.

Welding Together Extremely Thick Walls

The company supplied a robotic welding system to the Italian engineering company Simic where they were used for the construction of radial plates for the ITER. The plates were made from stainless steel, each with a wall thickness of 100 mm, and welding together these parts turned out to be an extraordinary challenge. The work is currently performed onsite, in southern France, with major requirements in terms of bonding precision and quality.

Hot wire TIG narrow gap welding turned out to be the best choice for welding together such extremely thick parts. The tool carriers for narrow gap burners, such as robots and welding trolleys, have been adjusted to suit the target object in both size and geometry. Narrow gap TIG welding, incidentally, can also be applied for pieces up to 400 mm in wall thickness.

Reaching For The Stars

Naturally, reliability and quality are greatly prioritised on the ITER project which has been in progress at the Cadarache Nuclear Research Centre in France since 2007. The Tokamaks chamber, which is surrounded by super-conductive magnets, is to serve as the place where the hydrogen isotopes deuterium and tritium are to be heated up to a temperature of 100million deg C, causing them to fuse. It’s a technology that reaches for the stars—quite literally, by seeking to imitate them. After all, it is nuclear fusion that enables the sun and the stars give off energy.

However, ITER has also drawn criticism, due to its immense expenses—estimated at over 15 billion euros (US$18.5 billion)—for one of the biggest building sites in Europe, coupled with a delay in completion. Advocates of the projects, on the other hand, see nuclear fusion above all as a highly efficient form of energy production, apparently generating 10 times as much in output. Moreover, it is considered to be an energy source without carbon emissions and virtually no radioactive waste. The first hydrogen plasma is expected to be produced around 2025. Robots, too, are helping towards the success of the ITER project.

Robots In Machine Processing

Sometimes it is the combination that matters. Twister, a bending system developed by Wafios, can even be used in pipe/hose combinations. To boost productivity, Wafios has linked the system to a robot from Kuka, and operation is simple.

Until recently, the focus has been mainly on handling processes where the demand on accuracy is relatively modest. Either the process chain included a processing tool with a specific element which compensated for inaccuracies —a polishing disc, grinding head or flexibly deflecting deburring spindle—or the issue of accuracy was more or less irrelevant. “Such handling processes are still often carried out by humans. However, due to increasing cost pressure, yet unchanging quality requirements or lack of human resources, they will be handled more and more by machines or automatically,” says Alexander Bailey, market segment manager, CNC/machining at Kuka Roboter.

China As A Future Market

It is a development which the company is prepared for. The general industry is growing very strongly, mainly outside Germany. “All you need to do is look at the electronics market which offers enormous potential for growth in automation,” said Mr Bay. Apparently, this is particularly true for Asia, and the focus on the general industry goes hand in hand with increasing internationalism.

Germany continues to be seen by the company as an important market for a robotic automation solutions. “However, we also believe that the big growth markets of the future are outside Germany and Europe. This is why we are focusing above all on Asia and, within Asia, on China, the country which—according to the International Federation of Robotics—has the biggest and fastest growing market for industrial robots.”

There are good reasons why the Middle Kingdom is considered to be the future market for robotics. It is already by far the biggest sales market in industrial robotics and is marked by extremely high growth rates. In three years’ time the International Federation of Robotics is expecting China’s annual sales of industrial robotics to rise to 160,000 items, which would then be nearly 40 per cent of all global sales.

Robots— Colleagues Of The Future

There can be no question that the use of robots already has enormous potential: Whenever the product quality is impacted by the workforce, robots have major potential. One important driver in the application of robots is considered to be the automotive industry.

And the end of this potential is still a long way off. Until now robots have mainly performed repetitive tasks, working at the same level of consistent precision and repeatability. “The requirements of the future will be different—especially in professional service robotics,” said Mr Bay. “If robots are to move into other areas, they will need to become more flexible, and this is where machine learning might help.”

Part of Industry 4.0

Robots are increasingly also entering Industry 4.0. Serving as flexible production elements, robots will be able to collect data in production and then exchange them with IT systems. “As a result,” said Mr Bay, “production routines will become even more efficient, and systems will be able to respond quickly to specific customer requests.”

Another trend is the simplification of programming. “This will include online connectivity for robots, enabling them, for instance, to import data from external systems, such as CAD,” said Ms Flaeper. It is apparently quite a challenge to use robots for very small production sizes—something which is still only possible to a limited extent.

Industrial & Private Environments

The company sees great future potential in the 3C, logistics and service/consumer robotics. Mr Bay also felt that robotics is increasingly moving from the highly organised sphere of industrial production into the more “chaotic” private environment. This is because artificial intelligence can help to prepare robotic systems for imponderables and changes.

Nevertheless, one thing is certain: “Robots will move closer to people, taking over even more tasks from humans and supporting them in carrying out certain difficult jobs,” said Ms Flaeper.

She posits an even more fascinating thought to ponder: “It would also be interesting if a robot could imitate the movements of a human being in a production process with a high level of accuracy, but without the need to be programmed.”

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

FOLLOW US ON: LinkedIn, Facebook, Twitter