Measure With The Right Twist Using ZEISS Articulating Stylus

High time and financial costs associated with frequent stylus changes is an articulating stylus, which can be motor-driven and software-controlled to replace multiple fixed stylus configurations, saving both time and money. ZEISS’ stylus shows how it’s done.

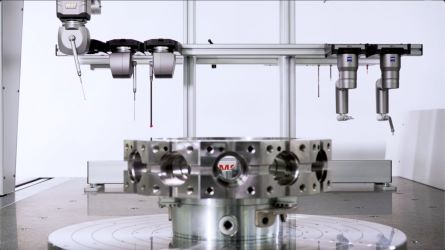

The probe changing magazines of some coordinate measuring machines (CMM) look like a bizarre cactus: dozens of probes of different lengths stick out like spikes in different directions, waiting to be used. This is sometimes necessary when complex components are inspected, maximum accuracy is required and a simple probe configuration is insufficient. This means a correspondingly large number of stylus changes are necessary, which results in high time and financial costs.

The remedy is an articulating stylus, which replaces several configurations with fixed styli, given it can be swiveled in one plane, motor-driven and software-controlled. For instance, it can be tilted upward at an angle to move into an opening that points downward at an angle.

This saves money because far fewer probes are needed, and it reduces the time required for initial assembly and determination of exact alignment, as well as for changing probes on the fly, especially for hard-to-reach workpieces. This white paper explains the advantages of a swivel probe and the applications for which it is particularly suitable. A cylinder head is used as an example to show how considerable the time savings are.

Five Probes Instead Of 15

This example will illustrate the advantages of an articulating stylus. A German automotive manufacturer previously tested a cylinder head with 75 inspection features to be measured using fixed styli.

The measurement is performed on two sides. Side A previously required seven fixed stylus configurations, while side B required eight, all of which were set up with different styli in all possible angular positions.

With an Articulating Stylus, these numbers shrink to two configurations for Side A and three for Side B. The fact that there is not only one configuration in each case is due to the fact that fixed styli may still be used for highly accurate individual inspection features.

The swivel stylus operates in one plane, and for another plane, another articulating stylus must be inserted that is rotated 90° about the z-axis. If more flexibility is required with an additional axis, it can be used in combination with a rotary table.

The Articulating Stylus therefore does not completely replace complex stylus configurations, but it does reduce their number and thus the time required for stylus changes considerably. In the example of the cylinder head, the time saved is 26% for side A and 15% for side B.

The time required to completely measure the cylinder head is reduced by 23% — a significant saving in the time- and cost-sensitive automotive industry, which typically has to wrestle for every percentage point of increased efficiency.

Read more here at page 38

What You Missed:

Chinese Enterprises Eye Manufacturing Opportunities In The Philippines

More Factories Relocate From China To Malaysia Over Restrictions

LG-Hyundai Electric Car Battery Factory To Open On 3 July 2024

Chinese Automakers Double Down On Presence In Thailand

Hitachi Industrial Equipment Systems’ ML Predictive Diagnosis Service For Air Compressors

TSMC Sees Annual Sales Growth To Reach 10% In Semiconductor Industry

Vietnam Versus Malaysia For Semiconductor Design Hub Crown

Vietnam Sluggish Auto Sales Hit Major Motorshow

Motional Flies Solo After Aptiv’s Curtain Call

Tesla Fired Its Supercharger Division – A Shocking Yet Brilliant Move

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

CONNECT WITH US: LinkedIn, Facebook, Twitter

Letter to the Editor

Do you have an opinion about this story? Do you have some thoughts you’d like to share with our readers? APMEN News would love to hear from you!

Email your letter to the Editorial Team at [email protected]