Wenzel Metromec: Metrosoft Quartis 15

Metromec Quartis R15 released by Wenzel Metromec has numerous added features. Additional functions in the work window “Feature data” display results directly, before the report is created at the end of the measurement program.

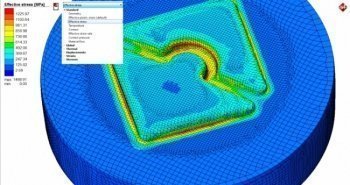

Simufact Engineering: Forming Simulation Software Simufact Forming 14

Simufact Forming 14 provides a graphical user interface that simplifies modelling and evaluation of simulation results. A new function is the pressure welding module which enables the simulation of joining processes by pressure and heat.

Hexagon: PC-DMIS 2017 R1

The first release of Hexagon’s PC-DMIS 2017 measurement software has several new features. Basic scanning operations are extended to QuickMeasure tools, while a new measurement strategy for AutoFeature Plane enables discrete point selection. QuickFeature selection is also now available in the Live View on optical CMMs.

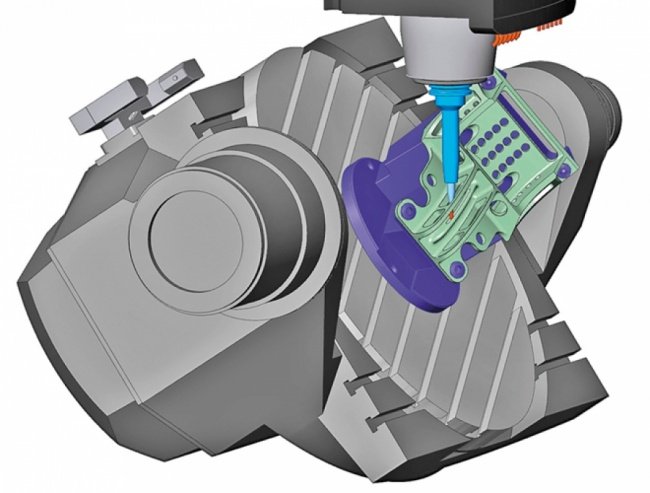

Multiaxis CNC Machine Simulation: A Confidence Booster

Multiaxis CNC Machine Machine simulation can go a long way into improving part quality and productivity. By Karlo Apro, product marketing, technical manager at CNC Software, Tolland, CT USA

A Better Way: Finding Efficiences Siemens PLM Software (Part 2)

Inefficiencies need to be ironed out before introducing the concept of the Digital Twin and what this means for the way goods are created and produced. By Siemens PLM Software, Aaron Frankel, senior marketing director manufacturing engineering software and Jan Larsson, senior marketing director EMEA

Machining Centres: Measurement Made Easy

Model and mould-maker Sammer, Machining Centres located in Eugendorf near Salzburg, Austria, is mostly engaged in the production of moulds for the automotive industry, including cylinder heads, crankcases and transmission housings. By Winfried Weiland, head of marketing, Blum-Novotest GmbH.

Zeiss: Comet L3D 2 3D Sensor

The Comet L3D 2 by Zeiss uses fringe projection with multiple lasers to measure 3D data. It automatically recognises changes in vibration and exposure, and its light yield and high measuring speed help to capture data on different object surfaces.

The sensor also uses colin3D software, from which false colour comparisons can be generated for analysis. With a resolution of 2,448 x 2,050, it has a working distance of 760 mm with accuracy of 20 to 40 μm depending on the choice of lens.

APMEN Products

CHECK OUT THESE OTHER ARTICLES

● Manufacturing Growth In Singapore Moderates After Eight-Year High

● Airbus Taps Hexagon Subsidiary To Reduce Development Lead Time

● Smart Data in the Metalworking Industry

● HAIMER To Showcase Latest Technologies And Solutions At EMO 2019

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

FOLLOW US ON: LinkedIn, Facebook, Twitter

Siemens: Solid Edge ST9 Software For CAD

Siemens has launched the new Solid Edge ST9 software for mainstream CAD. It allows easy access to the full capabilities of Solid Edge with cloud-based licensing, user preferences, and collaboration tools.

The built-in data management capabilities with zero IT support requirements enable users to easily index CAD models and allow users to take control of large volumes of CAD data, while the migration tools enable fast conversion of legacy design data from any CAD system. Additionally, a Solid Edge 2D to AutoCAD software export tool ensures an easy mapping of Solid Edge drafting elements to AutoCAD.

New cloud capabilities provide more flexible deployment options, improved user access and collaboration across remote designs teams. Licenses and user preferences can be stored on the cloud enabling users to easily access their personal environment at any time.

Solid Edge ST9 also adds data storage options via cloud-enabled vaulting so users can store and share design data in a controlled manner with external suppliers and customers, using popular software like Dropbox, OneDrive software, Google Drive online storage service and Box.

APMEN Products

CHECK OUT THESE OTHER ARTICLES

● GEORG At EMO 2019: Digital Twin Becomes Real

● ZYFRA Showcases AI Predictive Maintenance Software At EMO 2019

● HAIMER To Showcase Latest Technologies And Solutions At EMO 2019

● Walter’s HU5 Geometry Enhances Capabilities Of Cutting Machines

● Taking metal to the cloud

● The Carefree Package For The Entry Into Bending

● MVTec HALCON 19.11: Standard Machine Vision Software With New Functions

● Hexagon Launches QUINDOS 2019.2

● Round Tool Concepts: Indexable, Solid or Both

● Hypertherm Releases Major Version Update Of Robotmaster Robot Programming Software

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

FOLLOW US ON: LinkedIn, Facebook, Twitter

Makino: D300 5-axis Vertical Machining Centre

This 5-axis machining centre is designed specifically for small, complex, 3-D contouring of high-quality part production as typically seen in aerospace machining, medical manufacturing, high-end job shop and die/mould applications.

The D300 worktable offers a work area diameter of 300mm, accommodating workpiece sizes up to 450mm by 270mm and 120kg. The machine provides X-, Y- and Z-axis travels of 300mm, 500mm and 350mm, respectively, at feed rates of up to 60,000mm per minute. Rotary table axes offer rotational motion of 240 degrees (± 120 degrees) on the A-axis and a full 360-degree (continuous rotation) on the C-axis.

The machine comes equipped with a 15,000-rpm HSK-A63 spindle with 120Nm (42Nm continuous) of torque for flexible, high-speed machining of various workpiece materials including steel, aluminium and titanium. Optional spindle configurations include a 20,000-rpm HSK-A63 spindle and 30,000-rpm HSK-F63 spindle.

Makino uses direct-drive motor technology in the D300’s C-axis rotary table and A-axis trunnion for positioning accuracy and repeatability. The ultra-high-torque direct-drive motors also provide quality acceleration and rotary speed characteristics that can reduce cycle times of complex 5-axis simultaneous machining applications by up to 60 percent.

The D300 axis configuration is designed to deliver added precision performance. The length of the trunnion assembly runs parallel to the X-axis motion only, making the trunnion assembly deflection-free during quick axis motion for greater accuracy than traditional 5-axis configurations.

The machine features roller linear guides across all linear axes for rigidity and stiffness while maintaining productive rapid and feed rates. Y- and Z-axes are located above the worktable, with the X-axis located under the table to ensure a cantilever-free design and high positioning accuracies.

It employs the Makino Professional 5 Control, which provides a Windows CE graphical user interface (GUI) with touch-screen access, and the networking and storage capabilities of a data centre. This data centre features a flexible, user-friendly program and data management for quick, seamless changes from one setup to the next. Its built-in Ethernet networking capability offers ready integration to off-machine program storage.

Also featured in the D300 is the next-generation Super Geometric Intelligence (SGI.4) software developed specifically for high feed rate, tight-tolerance machining of complex, 3-D contoured shapes involving continuous tiny blocks of NC data that ensures production rates faster than standard CNC systems, while maintaining high accuracy. SGI.4 helps deliver the lowest cycle times and costs achievable by reducing machining cycle times on dies, complex cavities, and cores and medical parts by as much as 40 percent when compared to most other control technologies.

The tool centre point (TCP) control allows programming based on the tool tip so that tool-compensation features can be applied. Further TCP developments also improve the cutter path to achieve greater surface quality. Dedicated user-friendly screens simplify the overall application of 5-axis machining, and easy-to-apply functions prevent interference between the spindle and trunnion during automatic operation to improve risk-free production.

APMEN Product

CHECK OUT THESE OTHER ARTICLES

● Renishaw Demonstrates Additive Manufacturing Capabilities For Spinal Implants

● NCG CAM: Software

● ZAYER To Unveil Latest Milling Centre At EMO Hannover

● Tungaloy Introduces Full Profile Threading Inserts With Four Cutting Edges

● Okuma: Multus B 250 II

● Okuma: GA26W Grinder

● High Speed Accurate Machining

● MVTec HALCON 19.11: Standard Machine Vision Software With New Functions

● Predictive Maintenance and Machine Learning Will Revolutionise Reliability

● Heller: HF Series 5-Axis Machining Centres

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

FOLLOW US ON: LinkedIn, Facebook, Twitter