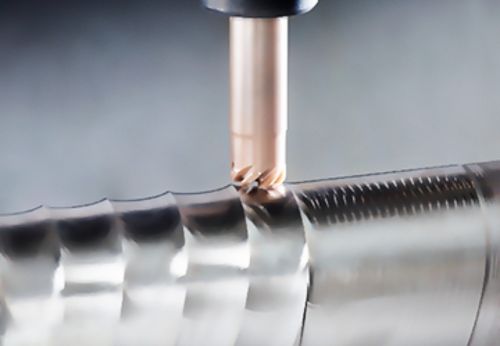

Solid Ceramic Endmills For Machining Nickel-Based Superalloys

Following the steady increase in the processing of nickel-based high temperature superalloys (HTSA) such as various grades of Inconel, Incoloy, and Haynes, amongst others, in the aerospace industry, and the demand to decrease production costs, ISCAR has launched solid ceramic endmills that enable increasing the cutting speed by up to 50 times when compared to carbide tools, drastically saving machining hours and reducing production costs.

Available in two configurations—E3, with three flutes for shouldering applications, and E7, with seven flutes, feed mill style for rough applications—the new endmills can also be successfully applied to productive roughing of cast iron and graphite.

The solid ceramic endmills are produced from two ceramic grades: IS6, designed specifically for machining HTSA, and IS35, intended for cutting mainly cast iron and graphite. They are available in 6mm to 20mm diametres.

Check these articles out:

● Round Tool Concepts: Indexable, Solid or Both

● Reducing Energy & Lubricants In The Automotive Industry

● Kennametal Makes Hard Turning More Cost-Effective

● Schuler Develops System For Die Monitoring

● A Look at Walter’s Two-in-One Machining Concept

● Sumitomo Electrical Carbide: AC8000P Series Grades For Steel Turning

● Etihad Engineering Sets Up 3D printing Lab in Abu Dhabi, Receives Region’s First Approval to 3D Print Aircraft Parts

● GF Machining Solutions Form P 350 Die Sinking Electrical Discharge Machining

● The Metal Machining Versatility of Abrasive Waterjets

● Hexagon Enhances Post-Processed Simulation, Automation Features In ALPHACAM

FOLLOW US ON: LinkedIn, Facebook, Twitter

READ MORE IN OUR LATEST ISSUE!

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!