hyperMILL® 2024 is the latest of OPEN MIND’s CAD/CAM suite, which delivers new turning features and improved algorithms. This makes the digital process chain more efficient, from CAD data and CAM programming to optimised NC code.

Open Mind hyperMill Virtual Machining

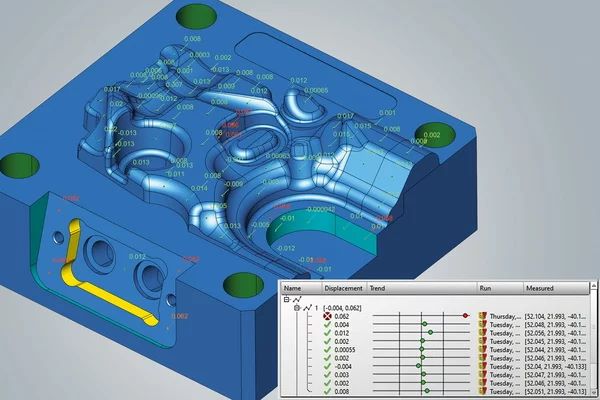

Open Mind’s hyperMill virtual machining software generates a bi-directional communication link between the machine control and the software for process control and optimisation. This allows for virtual mapping of the actual processes so that machining operations can be evaluated, checked and optimised before running the job.

The core software, called the hyperMill Machining Centre, virtually maps actual machining operations, including transition movements. This enables users to generate NC code-based simulations of virtual machine movements that match the machine movements in real life. Other modules have added functions, such as the Machining Optimiser that uses algorithms to determine tool position for effective traverse movements during machining.

Check these articles out:

● Flying Cut Gives Laser Cutting Productivity And Speed

● Taking ER Farther

● GF Machining Solutions Form P 350 Die Sinking Electrical Discharge Machining

● Bystronic To Showcase Laser Cutting, Bending Tech At Blechexpo 2019

● Hypertherm Intros Subscription Pricing Model for ProNest LT Nesting Software

● EMO Milano 2021: Meet “the magic world of metalworking”

● Hexagon Touch Probe Transforms Thickness Measurement on Machine Tools

● GEORG At EMO 2019: Digital Twin Becomes Real

● MVTec Expands Distributor Network in Southeast Asia

● TRUMPF Workmate: Digital Assistant for Sheet Metal Fabrication

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

Open Mind: Hypermill CAM Software

Open Mind’s Hypermill CAM Software features a range of machining strategies, from 2.5D and 3D solutions for high-speed cutting to 5-axis machining and mill turning. Special packages for machining of impeller, blisk and blade machining can also be found.

For example, the roughing module in the performance package includes numerous cycles for milling in trochoidal tool paths. The finishing module of the Maxx machining performance package includes pre-finishing and finishing of planes and free-form surfaces with various barrel cutters. All tool paths are checked for collisions.