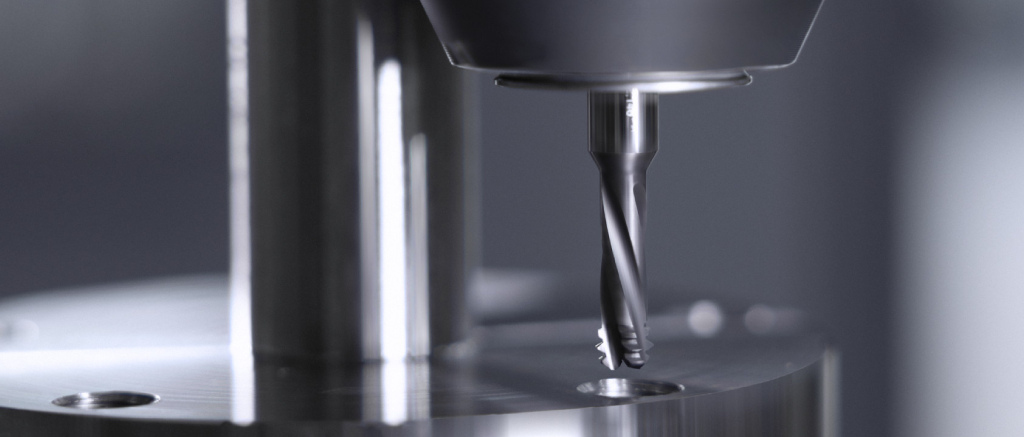

3-in-1 orbital thread milling cutters for new thread sizes

Walter expands its Thrill·tec TC645 Supreme range

Following the successful introduction of the Thrill·tec TC645 Supreme orbital drill/thread mills for dimensions from M4 to M12 in 2023, Walter is now expanding its range to cover additional metric dimensions from M14 to M20 as well as their imperial equivalents. These boast the same technical properties as the established versions – most importantly the ability to carry out drilling, chamfering and thread milling with just one tool. But for the first time, users are now also able to benefit from the exceptional efficiency of this 3-in-1 function for larger thread dimensions too. For instance, the longer paths of the machining program, which are common for large components, now only have to be traveled once instead of three times. This reduces non-productive time by two thirds.

Like all Thrill·tec orbital drill/thread mills, the new versions are also ultra rigid, suitable for universal use in all ISO materials P, M, K, N and S up to 48 HRC and boast integrated internal coolant. This enables reliable chip removal, especially with a high feed per tooth, extends tool life and ensures that blind holes and through holes are machined with both precision and process reliability. The combination of short machining times and long tool life reduces the cost per thread and means that the tools provide benefits both for mass producers and for users with smaller batch sizes. Walter offers special dimensions for delivery with a reduced delivery time of three weeks via its Walter Xpress service. In addition to the versatility, this means that users from a wide range of industries, such as mechanical engineering, aerospace or automotive construction, can also benefit from the rapid availability of the tools.

CONNECT WITH US: LinkedIn , Facebook, Twitter